Finishing

Paper and Cardboard Are Just the Beginning

In our pursuit of exceptional quality and creative diversity, we not only rely on traditional printing techniques but also incorporate high-quality accents like color pigments, metallic pigments, and varnishes. These elements give our print products unparalleled elegance and a touch of sophistication.

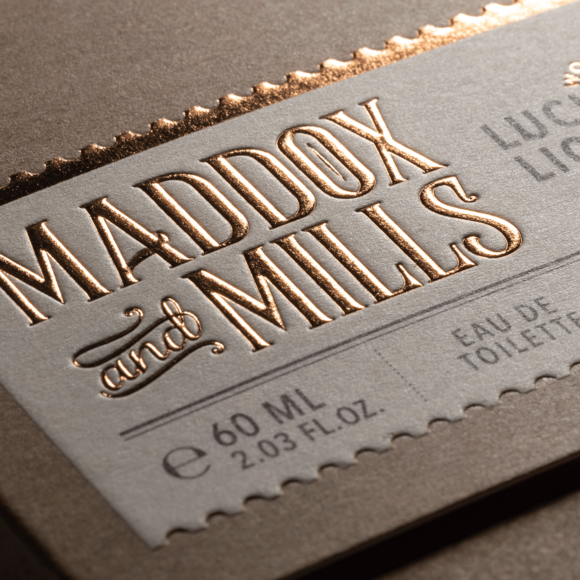

A remarkable technique we use to create captivating effects is hot foil stamping. Ultra-thin foils are applied to the printed sheet with precise pressure and intense contact. These foils add shiny, shimmering, or metallic accents that bring the design to life. Every step of this process demands the highest precision to ensure the foils are applied evenly and accurately.

Additionally, we employ foil and embossing techniques to give our print products a fascinating texture and visual depth. Using ultra-sharp tools, the finest lines and large areas are embossed onto the cardboard, creating an impressive tactile effect. This precise work requires the skills of experienced artisans who ensure that every detail is flawlessly executed with their trained eye and expertise.

Through the targeted use of these techniques and materials, we offer our clients a world of creative possibilities. We push beyond the traditional boundaries of printing, creating unique, individual, and impactful print products that present our clients' messages at the highest level. Our passion for precision and commitment to excellence form the foundation of every masterpiece we create.

We give your packaging that special something.

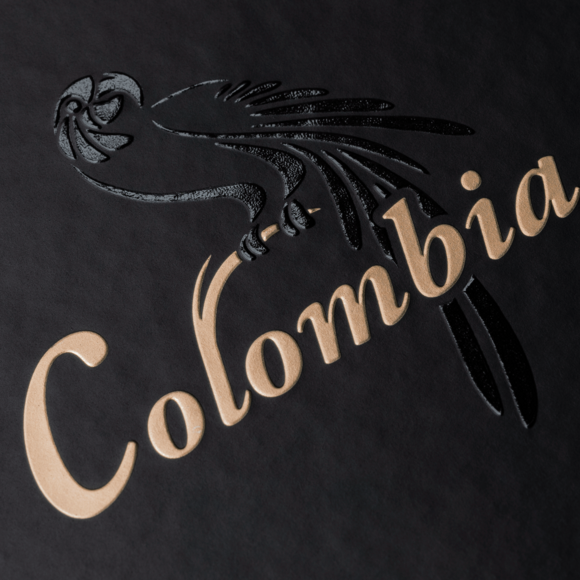

We focus on the tactile and visual effects of foil and texture embossing. The possibilities are immense. You can choose from a wide range of effect foils, and we will showcase your products.

This not only creates additional product value but also optimally conveys your brand image, all while maintaining consistently high productivity.

In hot foil stamping, specific areas of a design are embossed onto the cardboard using a heated plate and a metallic or color foil. The foil stamping incurs additional costs due to the extra tools, hours, and resources needed for embossing the foil after printing. Nevertheless, it is a cost-effective method to achieve an impressive effect that truly enhances the luxury factor of packaging.

The foils come in a vast selection of textures, colors, and effects, and we are happy to advise you.

In cold foil finishing, parts of the foil are applied to print substrates to create finishing effects. Unlike hot foil stamping, there are no cliché or tool costs, high temperatures, and complicated offline processes involved.

The foil is applied directly in the printing machine and can also be overprinted in color, allowing for a wide variety of effects. However, this method does not achieve the brilliance and elegance of hot foil stamping.

Whether glossy, matte, partial, or full coverage – varnishes create truly special effects: tactile, visual, and protective!

We offer a wide variety of varnish finishing options, from UV varnishes and varnishes with iridescent pigments to scented varnishes, covering every area.

In the processing of cardboard materials, technology has advanced remarkably in recent years.

One of these advanced innovations is the laser die-cutter, a machine that combines the advantages of laser technology with established die-cutting methods to achieve impressive results.